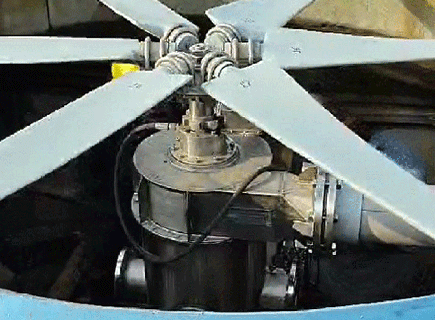

To run the Fan without any use of Electric Motor

With the increasing demand in Renewable Energy and urgency to reduce the usage of fossil fuels for power production, Pentaflo hydro experts have come out with a novel technology that could prove to be a great advancement in the field of energy conservation.

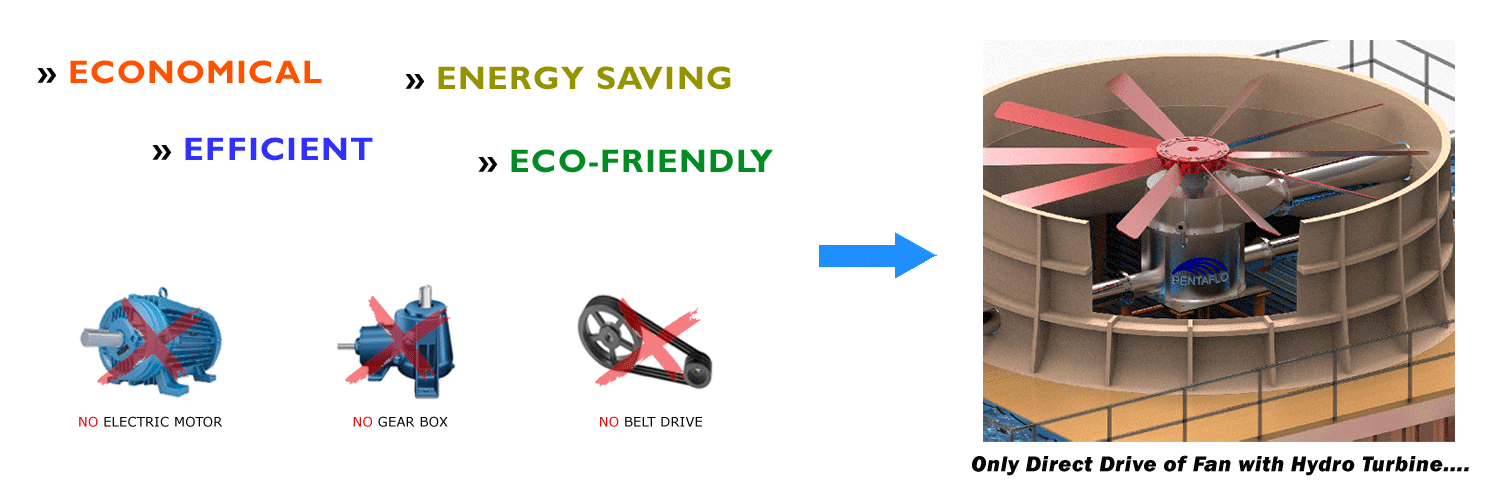

Cooling Towers employ high rated motors to rotate fans which assist the evaporative cooling in the system. Great deal of energy is consumed by the motors in this process resulting in higher electricity bills. In larger cooling tower plants, the low-speed fans require the provision of Belt-Pulley drive or gear boxes leading to additional operational and maintenance cost.

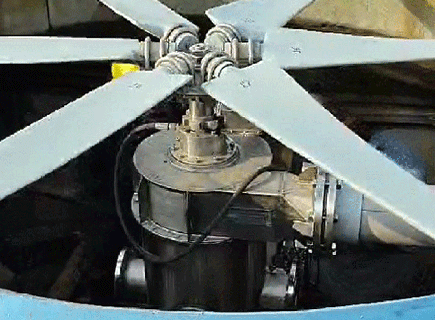

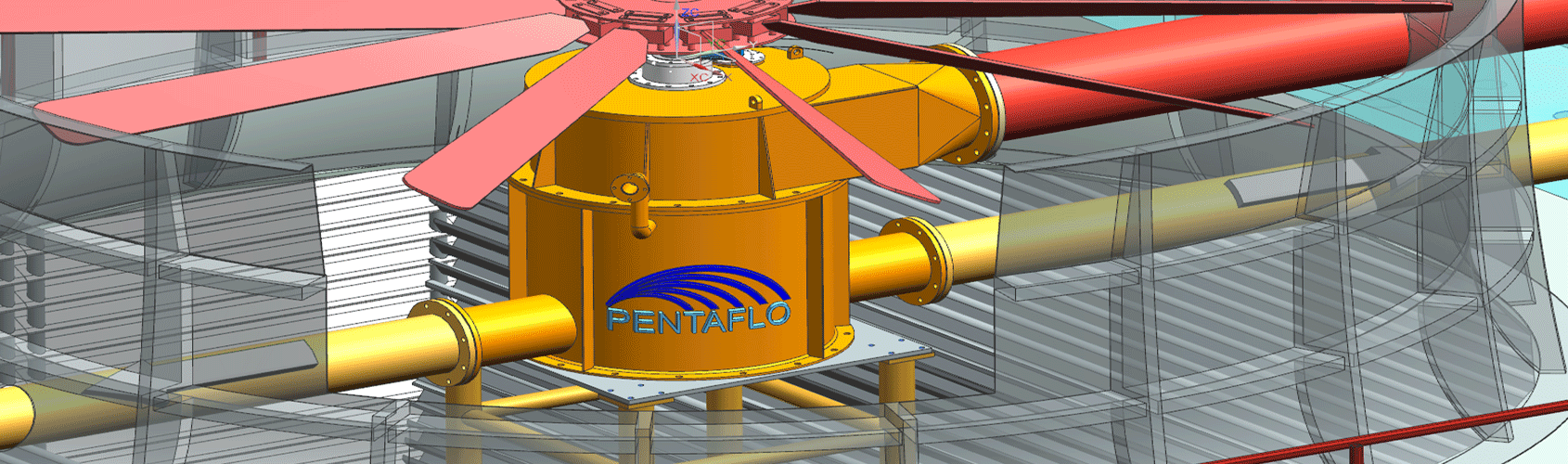

Pentaflo’s developed hydro turbine utilizes the circulating water residual pressure to rotate the cooling tower fan when it comes back to the cooling tower. The residual energy that goes waste in conventional system is converted to useful energy that rotates the cooling tower fan. Since there is no application of motors, the recurring electricity cost is eliminated in our new system.

This technology leads to considerable reduction in running cost & operational maintenance expense. There is no requirement of Gear Box, Gear Reducer or Belt Drive. Fan operates only direct with turbine.

Use our hydro turbine for reducing the electricity bills and carbon footprints of your cooling tower plants. Hence join hands with Pentaflo to build a green and sustainable tomorrow.

Pentaflo’s developed hydro turbine utilizes the circulating water residual pressure to rotate the cooling tower fan when it comes back to the cooling tower. The residual energy that goes waste in conventional system is converted to useful energy that rotates the cooling tower fan. Since there is no application of motors, the recurring electricity cost is eliminated in our new system.

Pentaflo’s developed hydro turbine utilizes the circulating water residual pressure to rotate the cooling tower fan when it comes back to the cooling tower. The residual energy that goes waste in conventional system is converted to useful energy that rotates the cooling tower fan. Since there is no application of motors, the recurring electricity cost is eliminated in our new system.